How HPC Designs Fire Features That Perform as Beautifully as They Look

At HPC Fire Inspired, flame is never an accident. Our team of incredibly talented engineers cultivates each component to produce the optimal flame patterns. Every flame pattern you see rising from an HPC fire feature, whether it is a standard PENTA burner or a TORPEDO style burner is the result of precise control over gas flow, air mixing, burner geometry, and materials. While the result is warmth and ambiance, the real value lies beneath the surface: efficient combustion, stable performance, and long-term reliability in real-world outdoor conditions.

HPC empowers consumers by educating what goes into every design. Understanding the engineering behind flame patterns and combustion efficiency reveals why HPC systems deliver consistent performance. Making it clear that HPC’s system stand above the rest. Take the opportunity to learn from the best gaining greater understanding of what lies beneath HPC’s signature flame.

Flame Patterns: Engineered Not Decorative

A flame pattern is the visible expression of combustion balance. HPC’s team of engineers account for all factors. Height, movement, and uniformity are all governed by how fuel and oxygen interact across the burner. Some key engineering factors include:

· Burner shape and layout: Efficient gas flow through the burner is critical to sustained flame patterns.

· Port size, spacing, and orientation: Ports are where the rubber meets the road. They are crucial for a tall sharp crisp flame.

· Controlled air entrainment: The amount of air pulled directly into and around the flame influences the flame shape, burning rate, and how much bi product soot is produced.

HPC burners are designed so each port delivers equal energy, creating flame patterns that are visually balanced and thermally effective offering stability. Proper porting of the burner layout ensures steady gas and airflow resulting in natural flame height allowing the flame pattern to stay consistent across the burner—enhancing both appearance and overall heat distribution.

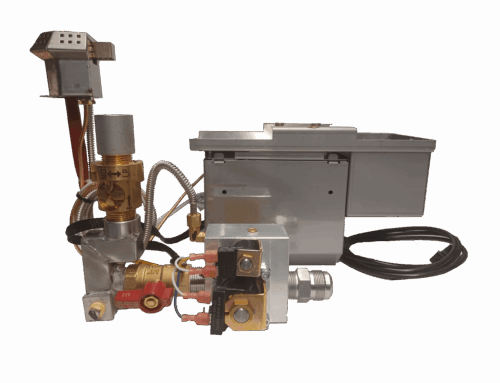

Gas Flow and Pressure Control:

Combustion efficiency begins with proper gas delivery. HPC systems from gas pressure to orifice sizing to burner capacity are all engineered to work together seamlessly. Too much pressure can cause:

· Flame lifting

· Noise and instability

· Excessive fuel consumption

Too little pressure results in:

· Weak or uneven flames

· Poor ignition

· Reduced heat output

HPC designs burners and control components as a system, ensuring the correct volume of fuel reaches each port under varying conditions. This system-level approach ensures reliable ignition, stable flames, and efficient fuel use.

Air Mixing: The Key to Clean Combustion

Efficient combustion requires the right balance of fuel and oxygen. HPC burner designs promote natural air aspiration—drawing in oxygen as gas exits the ports and ignites. When Primary air and combustion air are optimized:

· Flames burn cleaner with minimal soot

· Heat output increases

· Emissions are reduced

· Burner components experience less thermal stress

Poor air mixing leads to flame discoloration, carbon buildup, and wasted energy. HPC avoids these issues because the team takes proper action balancing all the key components. HPC produces safe reliable flames that are efficient and burn clean.

Heat Distribution and Combustion Efficiency

A well-engineered flame pattern does not just look better its’ flames performance is superior. Uniform flame distribution allows heat to radiate evenly across the fire feature, improving perceived warmth while using fuel more efficiently. Instead of chasing higher flames, HPC designs focus on effective heat delivery. The benefit of this engineered approach is:

· Improved comfort around the fire

· Reduced fuel waste

· Lower operating costs

· Longer component life

At HPC efficiency is not about less fire, it is about smarter fire.

Materials That Support Performance

Burner materials play a critical role in long-term combustion efficiency. HPC uses high-quality stainless steel and engineered alloys that:

· Resist corrosion and thermal fatigue

· Maintain port geometry over time

· Support consistent flame patterns season after season

Inferior materials can warp or clog, as well as disrupt air-fuel balance and degrade performance over time. HPC’s material choice is purposeful, by using high quality materials HPC invests in the integrity of every design.

HPC’s reputation for producing the best flame in the industry rooted in uncompromising engineering and decades of professional expertise. Every HPC appliance is curated, balancing precision gas control, superior burner construction, and durable materials that result in a flame that is fuller, more vibrant, and consistently reliable. From ignition to long-term performance, HPC engineers every detail to ensure efficiency, safety, and visual impact, setting a standard competitors strive to match.

When consumers choose HPC, they are choosing innovation, integrity, and a company that understands fire. HPC does not just manufacture appliances they light the way for the entire industry through thoughtful design and proven performance. Place your trust in the brand that professionals rely on and homeowners admire. To learn more or speak with an expert, contact HPC at 937-436-9800.