HPC Fire Inspired gas fire pits have become increasingly popular for creating cozy and inviting spaces in residential and commercial settings. Our fire pits, are exposed to a range of environmental conditions are are built and tested to withstand the harshest elements. HPC takes the utmost care ensuring the performance and safety of each design. One of the most crucial tests HPC runs is Thermal Testing of all outdoor gas fire features. In this article, we delve into the importance of thermal testing; taking a look at the testing and quality control process for our outdoor gas fire pits.

Top 4 Reasons For Ventilation:

Proper ventilation is key to safe operation and extending the longevity of your fire design.

- Venting provides space for potential trace gasses to be released from the enclosure. Whether your appliance utilizes natural gas (NG) or liquid propane (LP), there will be some residual or trace gas. Without proper ventilation gas can accumulate within the enclosure causing a potential safety issue.

- Proper venting allows excess heat to be released from the enclosure. In the case of HPC’s electronic fire pits, there is a thermal shut-off switch inside protecting the unit from overheating.

- Proper venting ensures fresh air flow for the pilot and burner creating combustion for ignition. For LP, venting provides clean air for the air mixer yielding a cleaner burn.

- Lastly, venting allows any residual condensation and moisture within the enclosure to evaporate.

An Inside Look: HPC Designs & Thermal Testing Fire Components

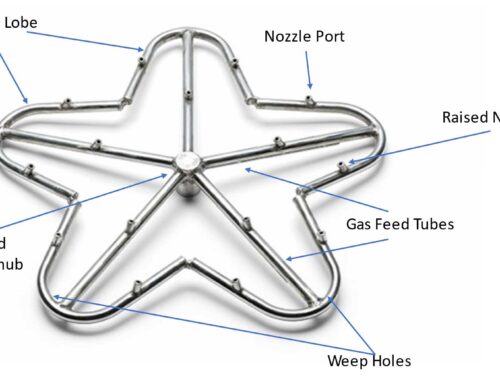

The heart of HPC’s gas fire pits are the signature burners. An HPC burner generates maximum heat while being built to withstand intense conditions and exposure to high heat. The selection of building materials matter. HPC utilizes high grade commercial 304 stainless steel. Our team carefully selected this material as it is resistant to corrosion, outdoor elements and high temperatures.

One way HPC can guarantee the longevity of our designs is through the use of Thermal testing. Thermal testing allows our team to simulate the extreme temperatures that a fire pit may experience during operation. By subjecting materials to these conditions, HPC can ensure that the chosen components and materials will maintain their structural integrity, preventing issues such as warping, cracking, or degrading over time.

HPC offers a vast variety of burners from our classic Standard Penta burner to our signature Torpedo burners made available in linear, H , S, and Penta styles. Every burner undergoes thermal testing getting HPC’s final stamp of approval. In addition, all HPC components from the valves, modules, thermal couples and igniters all undergo thermal quality and control testing. We stand by our designs giving our consumers peace of mind offering the longest guarantee within the industry.

Why Thermal Testing Is Important

HPC Fire Inspired Outdoor gas fire pits are constantly exposed to moisture, whether from rain, dew, or humidity. This exposure makes corrosion resistance a critical consideration. Using proper materials is imperative for the safety and longevity of the products. Therefore, through thermal testing, HPC has applied this critical knowledge to all of our product offerings.

Outdoor temperatures and the heat cycle of the appliance can vary significantly, leading to thermal expansion and contraction of materials. This phenomenon can cause stress on the components of a fire pit, or effect the sizing of the appliance, potentially leading to structural issues. This expansion and contraction must be understood to specify opening sizes for our appliances. Thermal testing helps HPC understand how materials respond to temperature fluctuations. Through continuous improvement HPC’s engineers are able to design fire pits that can withstand the rigors of changing weather conditions without compromising sizing or performance.

Ensuring the safety of HPC Fire Inspired’s outdoor gas fire pits is paramount. Thermal testing is an integral part of safety compliance, helping us identify potential concerns such as issues related to heat resistance or corrosion and how it relates to the materials used in the design of HPC’s fire features. HPC not only meets regulatory CSA standards for rigorous testing, but exceeds these standards and provides internal component and whole appliance testing prior to every design being packed and shipped to our consumers. This ensures the quality and integrity of every HPC Fire design.

HPC’s designs are not only safe and functional, but every design offers an appealing aesthetic that enhances your outdoor entertaining space. Thermal testing allows us to strike a balance between safety, durability, and design. HPC’s engineers thoughtfully select materials that meet the demands of the designs; offering manufacturers and consumers products that are high-quality and priced reasonably.

HPC works diligently from the point of the conception of the design to testing every appliance ensuring the highest quality for our consumers. Consumers are often bombarded by an over saturation of options. Partnering with HPC gives consumers peace of mind. When consumers invest in an HPC design they are getting specially curated creations that exceed industry standards.

HPC strives for continuous improvements and rigorously evaluates materials under various temperature conditions to ensure that our products are not only aesthetically pleasing but also durable, safe, and able to withstand the challenges posed by outdoor environments.

If you have any questions or concerns, please give us a call at

937-436-9800. Let our NFI certified technicians provide guidance around all your fire design needs.

Looking to learn more about HPC’s Offerings? Schedule an online or in person training with Chuck Parsons, HPC’s training and education manager.