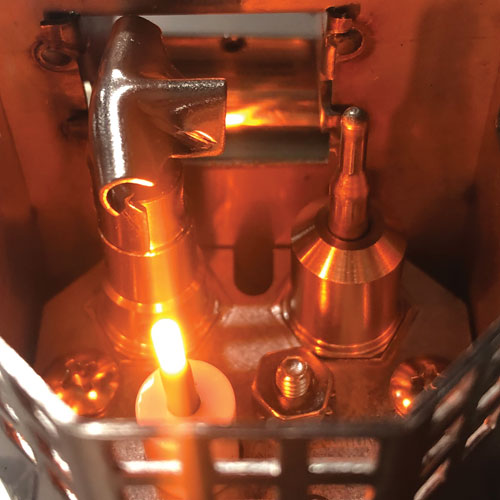

Ignition systems are vital components in gas-fired appliances, providing the means to initiate combustion by igniting the gas-air mixture. Over the years, various advanced ignition technologies have been developed, each offering unique advantages in terms of efficiency, reliability, and performance. In this article, we will explore some of these advanced ignition technologies and materials including hot surface igniters, plasma igniters, and other innovative approaches for fuel ignition. In addition, we will outline why HPC Fire Inspired chooses to use the hot surface igniter in our electronic ignition fire features.

Hot Surface Igniters

Hot surface igniters are critical components in many gas-

fired appliances, providing a reliable method for igniting the gas-air mixture. While silicon nitride and silicon carbide are commonly used materials for hot surface igniters, there are a few other types worth mentioning:

- Silicon Carbide (SiC) Igniters: Silicon carbide igniters are widely used in gas appliances due to their high thermal conductivity and durability. They can withstand high temperatures as well as rapid temperature changes, making them suitable for demanding applications.

- Silicon Nitride (Si3N4) Igniters: Silicon nitride igniters, offer similar advantages to silicon carbide igniters. They are known for their strength, thermal shock resistance, and reliability in igniting gas burners.

- Microcontroller-Based Igniters: Some modern hot surface igniters incorporate microcontroller technology to improve performance and efficiency. These igniters may include features such as temperature monitoring, adaptive heating algorithms, and diagnostic capabilities to ensure optimal ignition performance and reliability.

- Ceramic Igniters: In addition to silicon-based materials, ceramic hot surface igniters made from other materials like alumina (Al2O3) or zirconia (ZrO2) may also be used in certain applications. These ceramic igniters offer high temperature resistance and mechanical strength, making them suitable for harsh operating conditions. Ceramic Igniters come at a higher cost when compared to other ignition systems`.

- Carbon Igniters: Carbon-based hot surface igniters, sometimes referred to as carbon glow igniters, utilize the electrical resistance of carbon to generate heat for ignition. They are less common than silicon-based igniters but can offer advantages in specific applications.

- Composite Igniters: Some hot surface igniters combine different materials or use composite structures to achieve specific performance characteristics. For example, a composite igniter may combine silicon carbide or silicon nitride with metals or other ceramics to enhance durability or thermal conductivity.

These various types of hot surface igniters offer HPC flexibility in designing our fire features to meet specific requirements for performance, durability, and cost-effectiveness. The choice of igniter depends on factors such as the operating environment, ignition system design, and performance objectives of the appliance.

At HPC durability and cost effectiveness play a major factor in selecting the correct igniter and igniter material for our appliances. HPC Fire Inspired elects to utilize the Silicon Nitride Hot surface igniter in most instances. This is because of its superior durability compared to other hot surface igniter material. While other igniters such as a Carbon igniter or a Silicon Carbide are available at lower costs, these materials tend to be more brittle and can’t hold up to the demanding elements that outdoor fire features face. The Silicone Nitride Igniters however can withstand the harshest of outdoor elements while providing high quality performance offering reliability and longevity.

The Future Of Hot Surface Igniters

Our team is always striving for continuous improvement to offer our consumers the latest and greatest advancement in technology. HPC Fire Inspired is actively testing and developing a Plasma igniter, for future generation appliances. Hot surface igniters, work by heating a solid surface to high temperatures, causing the gas mixture to ignite upon contact with the hot surface. Plasma igniters generate a high-temperature plasma arc to ignite the gas-air mixture. Plasma is often referred to as the fourth state of matter and consists of ionized gas molecules containing free electrons and ions. In a plasma igniter, an electrical discharge is used to create a plasma arc, which serves as the ignition source. This advancement offers consumers greater efficiencies.

Stay tuned as our HPC Fire Inspired Team develops this innovative Plasma Igniter technology. Stay in the know and be sure to subscribe to HPC Fire Inspired’s news letter.

Advanced ignition technologies play a crucial role in improving the efficiency, reliability, and performance of gas-fired appliances and combustion systems. Whether it’s hot surface igniters, plasma igniters, or other innovative approaches, each technology offers unique advantages tailored to specific applications. By understanding these advanced ignition technologies, manufacturers can design more efficient and reliable gas appliances to meet the evolving demands of consumers and industry standards.

If you have any questions or concerns, please give us a call at 937-436-9800. Let our NFI certified technicians provide guidance around all your fire design needs.

Looking to learn more about HPC’s Offerings? Schedule an online or in person training with Chuck Parsons, HPC’s training and education manager.