HPC Fire Inspired is often confronted with many important questions about our Gas Fire Features. Proper gas line sizing is a recurrent question that requires a thorough response. So, how does one know the proper gas line size for their unique design? This Tech Talk will walk you through the important factors to take into consideration when planning the installation of your new HPC Fire Design. Knowing these key factors will ensure your design performs optimally as well as remains safely and reliable. In addition, consumers will gain a comprehensive understanding around gas line sizing calculations enabling them to make informed decisions about their gas appliances.

Why Gas Line Sizing Is Important

Ensuring fire appliances receive an adequate supply of gas is essential for their safe and effective operation. Gas line sizing, though often overlooked by consumers, plays a crucial role in maintaining proper gas pressure and flow rates to appliances. There is so much that goes into calculating proper gas line sizing. Each factor must be honored to support the overall functioning of our designs.

Features Of Gas Types

Before delving into gas line sizing calculations, it’s essential to understand the properties and behavior of gas within piping systems. Natural gas, the most commonly used fuel in residential and commercial applications, behaves as a compressible fluid. How Natural gas flows is influenced by factors such as pressure, temperature, and pipe diameter. Gas pressure drops along the length of the pipe due to friction and other losses, affecting its velocity and flow rate.

Gas Demand

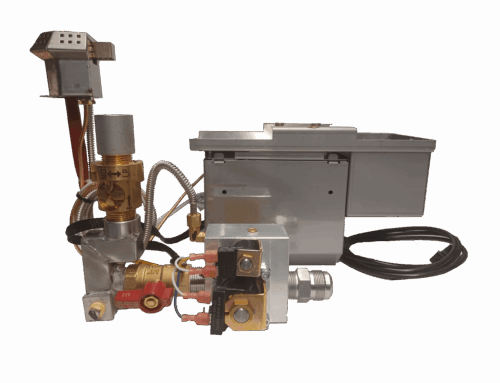

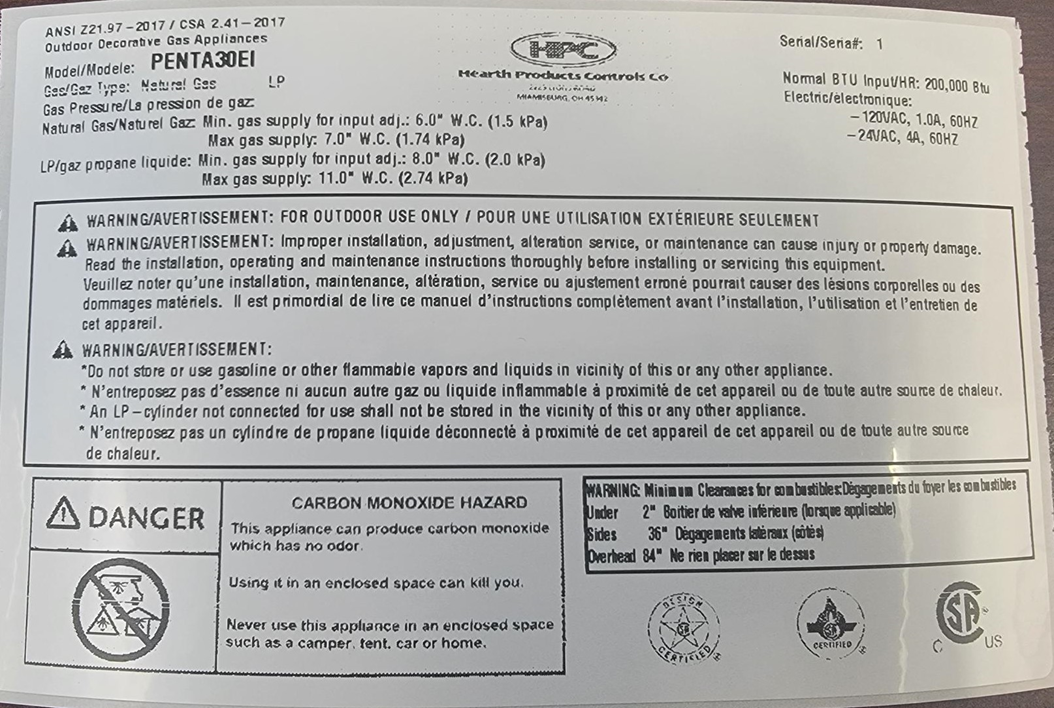

Determining the gas demand for a specific application is the first step in gas line sizing. Gas demand is typically expressed in terms of British Thermal Units per hour (BTU/hr) or cubic feet per hour (CFH). To calculate gas demand, factors such as appliance type, burner capacity, operating hours, and simultaneous appliance use must be considered. HPC provides gas specifications for our appliances that can be found on our appliance data plate located under the burner pan (fig.1). This label outlines gas consumption rates, which are used in demand calculations. The label provides BTU/hr rating, gas pressure requirements along with other important information.

Figure 1

Gas Line Sizing Methods

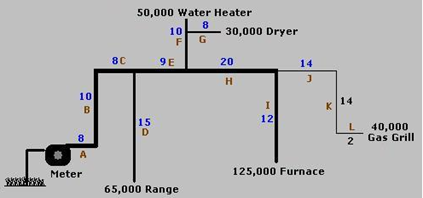

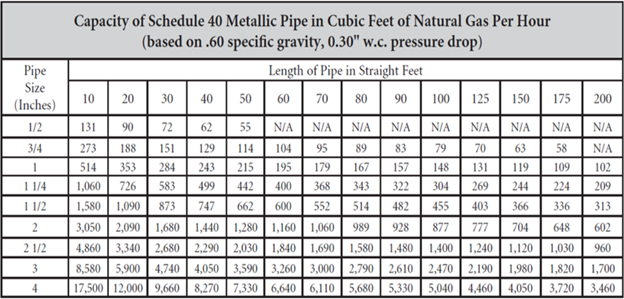

HPC utilizes the ‘Longest Run and Load” method to calculate proper gas line sizing (fig.2). This method involves calculations based on gas demand, pressure drop limitations, gas pipe type and pipe sizing tables (fig.3) These standards are provided by regulatory bodies such as the American Gas Association (AGA) or the National Fuel Gas Code (NFPA 54). Engineers and designers must select the most appropriate method based on the system layout, gas load, and applicable regulations.

Figure 2

Figure 3

Compliance With Codes

Compliance with relevant codes and standards is paramount in gas line sizing to ensure safety and reliability. The NFPA 54, also known as the National Fuel Gas Code, and the International Fuel Gas Code (IFGC) provide guidelines for the design, installation, and maintenance of gas distribution systems. These codes specify requirements for gas pipe sizing, material selection, pressure ratings, venting, and combustion air supply to prevent leaks, fires, or explosions.

Summary

Gas line sizing is a complex process that requires a thorough understanding of gas properties, demand calculations, sizing methods, pressure drop analysis, and code compliance. With this information, it is clear there is so much that goes into proper gas line sizing. Our certified NFI technicians can provide consumers and gas technicians proper BTU rating for fire features and relay the proper inlet pressure of the appliance to set you up for a successful installation. However, without being onsite to understand the characteristics of the gas piping system being used it is difficult to provide further guidance. It’s HPC’s hope that by educating consumers and professionals as well as by following established principles and guidelines, that this will ensure the safe and efficient operation of all HPC Fire inspired designs in residential and commercial settings.

If you have any questions or concerns, please give us a call at 937-436-9800. Let our NFI certified technicians provide guidance around all your fire design needs.

Looking to learn more about HPC’s Offerings? Schedule an online or in person training with Chuck Parsons, HPC’s training and education manager.