It’s All About Stainless Steel

Benefits Of HPC’s Stainless Steel Torpedo Burner

John A. Shedd once said, “A ship in the harbor is safe, but that is not what ships are built for.” HPC’s Research and Design Team Lead by our top-notch Engineers breathes life to this quote with each design they create. Partick Schatz, an HPC engineer speaks to the extensive research that goes into each piece. He states, “Our product designs are carefully curated, with safety at the forefront while HPC’s testing team proves out functionality and performance before each design is approved.” This Tech Talk is dedicated to the brilliant design of HPC’s Stainless Steel Torpedo Burner and will also provide a comparison to a Jetted Brass Burner. HPC’s research will leave you well informed of all the benefits regarding functionality and performance the Stainless Steel Torpedo Burner will offer you.

Stainless Steel (SST) Torpedo Burner:

HPC’s appliances, offers the new SST Torpedo burners which are independently certified by CSA. The Torpedo burner is made with Commercial grade stainless steel and is outfitted with our patented fuel efficiency nozzle design, as well as our welded burner nozzle components. These features allow the flame to burn both quiet and clean. This burner is truly inspired by proven technology delivering safety and outstanding performance for all our consumers. When you purchase the SST Torpedo Burner, HPC provides a hassle free lifetime guarantee that covers your unit completely. Let us dive deeper and discuss the features of the Stainless Steel Torpedo Burner compared to the Competitor Jetted Brass Burner. You will plainly see that HPC’s SST Torpedo Burner rises to the top and easily overcomes issues that cause the Brass Burners to fail.

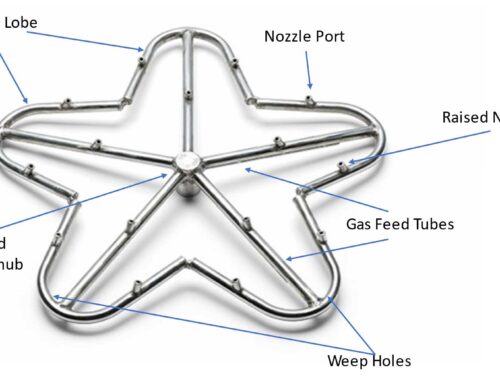

Water Abatement:

HPC’s Research and Design Team conducted an extensive 8 hour Rain Test on both the SST Torpedo Burner and the Competitor Jetted Brass Burner. This 8 hour real world test replicated the parameters and equipment setup as performed at the CSA testing lab per ANSI standards. Over the 8 hour time period, the Jetted Brass Burner began to fill with water causing the flame to extinguish. In addition, Per Patrick Schatz, “ As the Brass Burner began to fill with water it made an audible gurgling noise, this indicates that the ports that supply the gas were filling with water and spilling over into the pan causing an unreliable flame.” The Brass Burner’s orifice is located above the surface on each port which increases the chance of water encroachment and can lead to long term issues such as clogging and corrosion. In comparison, HPC’s SST Torpedo Burner stood the test of time and continued burn brilliantly over the course of the 8 hour period. Per Chuck Parsons, “HPC’s orifice is located below the pan allowing it to be protected from the elements. HPC’s raised hub design and strategically placed weep holes are essential to guiding the water away from the source of the gas and the controls enabling the unit to light every time.”

Corrosion:

When a fire pit unit develops corrosion it becomes faulty. As Brass is exposed to elements over the course of time a white powdery byproduct develops which can block burner holes and tubes. The substance blocks gas flow causing the unit to underperform. The Competitor warranty is limited and requires customers to perform a number of tasks to ensure coverage. For instance, it is required that the fire pit be covered when not in use. Failing to do so will void the warranty. In contrast, HPC utilizes commercial stainless steel that can withstand weather conditions. HPC values our customers and offers a lifetime warranty which guarantees the quality and performance of the designs without any stipulations.

Noise:

After a hard day at work you want to retreat and enjoy great company by a quiet fire allowing you to reconnect and recharge. The Jetted Brass Burner is prone to more noise due the chosen design. The Brass Burner utilizes threaded components and side vent holes used to suck air to support the flame exiting the nozzle. The result is the Brass Burner air mixing is more prone to blockage which causes these burners to burn louder. Per Patrick Schatz, “While performing testing, the Brass Burner reached a higher frequency decibel.” In Contrast, HPC’s patented SST Torpedo Technology utilizes welded directional ports, strategically placed orifice holes that create even distribution of pressure which work together to yield a quiet burn. HPC’s quiet burn technology allows our customers to create those memorable moments.

Quality and Performance:

Maya Angelou once said, “When you know better you do better. “ HPC values knowledge and invests in the exploration of best practices as well as engineering to ensure quality and performance from each of our fire designs. The SST Torpedo Burner outperforms the Brass Burner at every turn. HPC’s Torpedo Technology creates a superior flame, burning cleaner, quieter, brighter and longer. We stand by our units with our lifetime guarantee, promising it will light every time rain or shine.

Now that you know better you can do better. Any questions or concerns contact our Certified National Fireplace Institute Tech Team at 937-436-9800 or at Info@HPCFire.com.