I’ve Seen Fire And I’ve Seen Rain But An HPC Flame Will Sustain:

HPC’s Water Mitigating Technology

HPC Fire Inspired Research and Design Team invests in our customers by raising the fire industry standards with their innovative designs. Purchasing an HPC Fire Inspired Appliance will guarantee you a quality design with unparalleled performance, ease of use, and the latest technological conveniences. This Tech Talk will highlight the technological advances HPC has made to promote proper drainage and ventilation in all of our appliances which mitigate water damage from the elements. In addition, HPC will provide education around the importance of installing proper drainage as well as ventilation systems when inserting HPC’s signature fire components in an enclosure. Doing so will ensure HPC’s brilliant flame will sustain.

HPC’s Water Mitigating Technology:

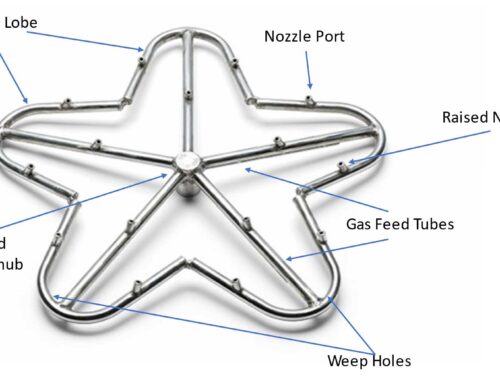

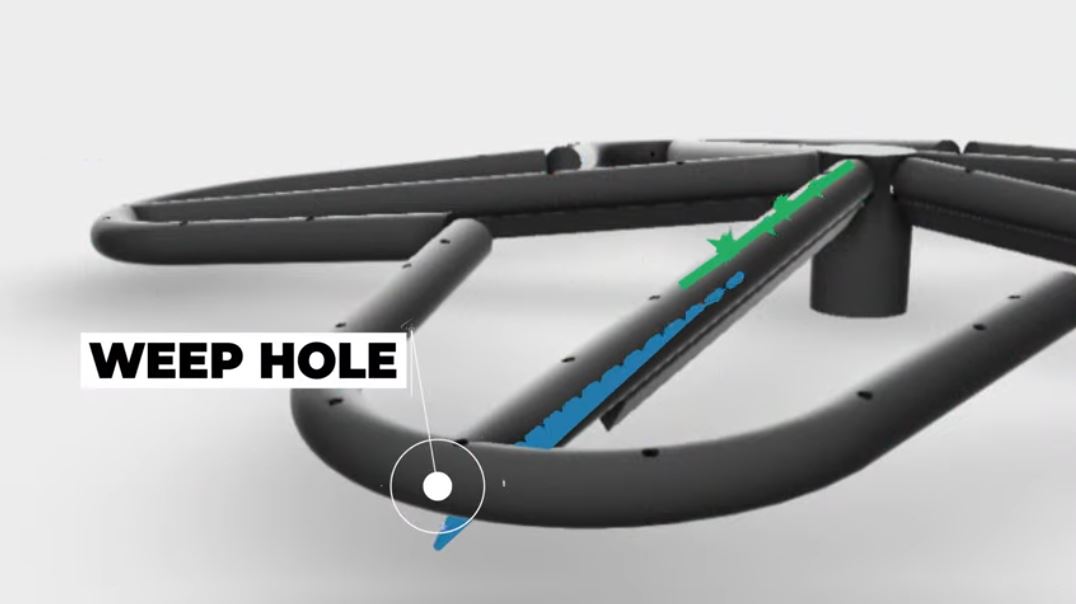

HPC has made several critical technological advances that mitigate water issues due to outdoor elements. HPC utilizes commercial grade stainless steel to create all fire components. Using quality materials allows our units to withstand severe weather conditions. From the construction of the pan to the use of a manifold, each component plays a crucial role in the designs’ quality and functionality. HPC’s Pans are constructed with stainless steel and have strategically placed weep holes to allow for drainage. In turn, the weep holes deter water from collecting in the pan itself. Every HPC burner utilizes a raised hub design with weep holes located on the ends of the burners. The raised hub guides water downward and out toward the weep holes. The tooled weep holes are approximately 3/32 of an inch. HPC’s module utilizes potting technology that makes it certified for outdoor use by CSA and ANSI standards. The potting material is made of rubber and prevents water from getting in. HPC’s assembly technicians also utilize a layer of dielectric grease which is water repellent and further protects the module. The next line of defense is the Manifold. The leg or sediment trap guides water away from the valve. This evolution in design creates another layer of protection for the valve and the valve box by shielding it from the elements. While our competition locates their air mixing technology at the surface, HPC’s air mixer is installed underneath the pan protecting it from the elements lessen risk for water issues. Lastly, HPC installs valve box ventilation which has increased air movement and ventilation. Doing so, keeps the valve and the valve box dry and properly ventilated even in the face of storms. By investing in the advancement in technology HPC invests in the customer experience. Purchasing an HPC Fire Inspired Appliance will guarantee you a quality design with unparalleled performance, ease of use, and the latest technological conveniences.

Installer & Owner Responsibilities For Drainage & Ventilation:

Thanks to the advancement in technology HPC has made, we no longer see water retention in the valve box. To further support the technological advancements, it is essential that proper drainage and ventilation are planned for when building an enclosure. Without proper drainage and ventilation in an enclosure water can and will accumulate. When HPC’s technology is submerged in water it can not work effectively and can cause serious damage. Therefore drainage and ventilation in an enclosure are key to creating optimal conditions for HPC fire appliances.

In terms of drainage, HPC recommends utilizing a floor drain inside the enclosure, as it is not as susceptible to blockages. In instances where a floor drain is not possible, HPC advises creating ventilation openings at ground level. Doing so allows any water from elements to naturally flow out of the enclosure. When creating an enclosure from masonry, brick, stone, or pavers one can intentionally leave gaps in mortar at ground level making way for any water in the unit to drain out. Taking care of these critical steps at the point of installation will mitigate issues with water collection protecting your valuable investment.

Creating proper ventilation in an enclosure is another critical step that must be taken at the point of installation. HPC recommends that ventilation ports should be created at ground level. Doing so, aids in drainage as well as reduces any naturally occurring condensation. Strategically place venting as well as HPC’s weep holes allow any water or moisture a direct route out further protecting your investment.

Following the proper installation instructions and maintenance will ensure the performance and longevity of your investment. Be sure to check out HPC’s Smart Apps, as the technology offers step by step guidance for installation and assists with trouble shooting any issues. In addition, HPC’s Tech team is only a phone call away and will gladly impart their knowledge and expertise.

Managing The Elements:

One way to maintain your fire appliance is to utilize an HPC cover while not in use. However, If an appliance burner is exposed during a storm HPC recommends igniting the unit for approximately 30 to 45 minutes. Doing so will facilitate the evaporation of any standing water left in the appliance. A Pro Tip from HPC, as stated by Chuck Parsons, “To extend the longevity of your unit it is best to run it regularly and when not in use it is best to keep it covered.”

Customer Satisfaction:

HPC values knowledge and invests in the exploration of best practices as well as engineering to ensure the quality and performance of each fire design. HPC stands by the integrity of our units and offers our customers lifetime guarantee warranty. Refer to HPC’s warranty guidelines servicing all of your needs.

Let our dedicated Certified National Fire Institute Tech Team as well as our Customer Specialists field any questions or concerns. Our team will walk you through the process from start to finish ensuring your fire appliances exceed your desires. Reach our HPC Fire Inspired Team at 937-436-9800 or at Info@HPCFire.com.

Buying HPC we can guarantee that in spite of rain HPC’s Flame will sustain.