Hearth Product Controls (HPC) specializes in fire pit inserts. In order to have a successful installation of an insert you must build the proper enclosure, which means, ensure good drainage, meet product clearances and understand ventilation requirements.

An HPC fire pit insert is different than a fire table. An insert is a permanent installation, requires a hard piped gas line, possibly an electric or GFCI outlet run into the enclosure. The enclosure can be built to match or blend with your outdoor area, whether stone, brick, poured concrete or several other possibilities.

No matter what you choose, there are 3 reasons you still need to build in ventilation.

- Vent any trace gasses from the enclosure. Whether natural gas (NG) or liquid propane (LP) there will be some residual or trace gas that must not be allowed to accumulate in the enclosure.

- Remove excessive heat from the enclosure. In the case of electronic fire pits there is a thermal shut off switch inside the unit to protect from heat.

- Combustion air for the pilot/ignition. Provides fresh air for the pilot and burner and with LP provides clean air for the air mixer to pull in for cleaner burn.

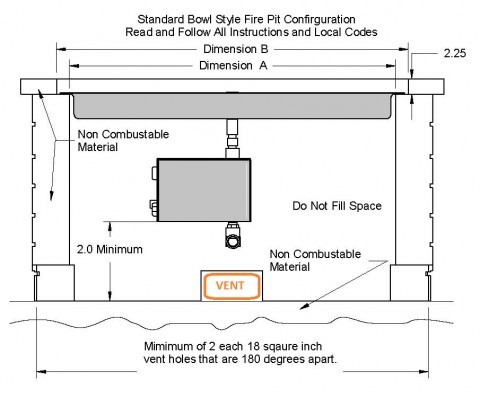

Now HPC installation instructions recommend a minimum of 2 vent openings on opposite sides at 18sq inches each and prefer 4 to reduce the risk of thermal shutdown on the EI Series . This equates to about a standard size brick removed on 2 sides. The size and shape of the openings can be altered to match the design, example 4 vents on a square enclosure, one on each side at 9sq inches each. Vents can be located towards the top, middle or bottom. At the bottom, grade level, also serves as a means of drainage

Why 2 vent openings? Remember we are trying to MOVE air through the enclosure, not draw in for combustion air only.