Troubleshooting The Dreaded Whistle: It’s Not The Burner

HPC’s Certified NFI Tech Team is ready to service all your needs. Chuck Parsons’ shares a consumer issue centered around a whistling noise emanating from their fire appliance. Per Chuck Parsons, “ consumers often believe that the whistling is coming from the burner, but in fact there are several components HPC Techs walk our consumers through to address their concerns.” Chuck Parsons goes on to explain that the reason it appears that the sound is coming from the burner is because the sound resonates through the appliance leading the consumers to believe that this is in fact the source of the issue. In this Tech Talk, HPC would like to discuss the source of the whistling noise and offer resolutions as well as precautions to take to avoid the dreaded whistle.

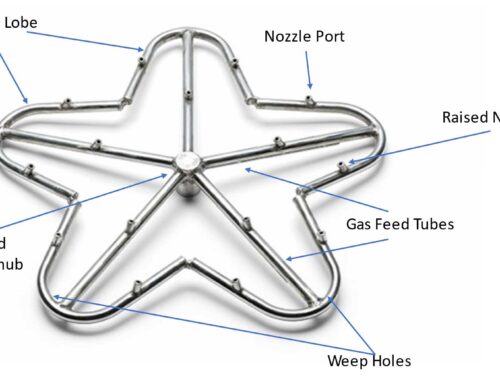

HPC’s Design:

HPC takes special care when designing and engineering each component of every fire appliance. When creating the ports on our signature stainless steel burners, HPC elects to drill them out versus punching the ports. Drilling creates a more finished hole allowing gas to flow freely. All HPC burners have an orifice attached, which controls the amount of gas that goes to the burner. The drilled ports as well as the use of the tooled orifice create a quiet burn.

Check Your Flex Line:

When there is a whistling noise coming from your fire appliance, the most common culprit is the Flex Line. Per Chuck Parsons’, “When HPC’s tech team is made aware of this issue we guide the consumer to check their Flex Line.” First, check to make sure that there are no kinks in the line as this can create bottlenecking at certain points which can cause pressure to build up. This causes the line to vibrate which in turn creates a whistling noise. While Flex Lines are created to bend, if the line is bent at too tight of a radius it will create a build up of pressure. In turn, the overcorrected line contributes to the gas on the inside of the line moving at a higher velocity than the outside gas. The difference in velocity creates the whistling sound as the gas travels across the ridges of the line. When checking the Flex line make sure that it is not bent too far. Next, check that the tip of the line where it connects with the fire appliance has a large radius. The larger the radius in the line the less likely the whistling sound will occur, as tight bends create the dissonance. One way to assure your fire appliance remains whistle free is to purchase HPC’s Tranquil Whistle Free Flex Line. Check out HPC’s Fire Pit Components and consider purchasing the line to ensure ease of use and proper fitting. The lines are available in 12 inches, 18 inches, 24 inches and 30 inches. The lines are made from stainless steel and are 3/8” in diameter.

Check The Gas Pressure:

If the whistling sound persists, the next step is to check the gas supply. The whistling noise could be attributed to the gas pressure supply being too high. If the gas pressure running through the line is too high, the velocity of the gas can cause the whistle sound. HPC recommends contacting a certified gas plumber to determine how much gas pressure is going through the flex line. In turn, the provider can assess proper gas pressure and make appropriate changes. One quick fix HPC offers is HPC’s Gas Line Regulator. Installing a regulator allows consumers to control the gas pressure with ease.

Gas Line:

Lastly, if the the whistling persists it could be due to a faulty gas line. In this instance, HPC recommends contacting a Gas Technician. The Tech will inspect the line upon disconnecting it from the source and open up the valve. If the whistling persists the gas line is the culprit and a new line will need to be run.

Customer Satisfaction:

HPC values quality and safety ensuring that all our of our appliances have been tested to guarantee their reliability and security. If you have any further questions or concerns, reach out to HPC’s Certified NFI Tech Team at 937-436-9800. Our team is ready to support your every need.